Challenge

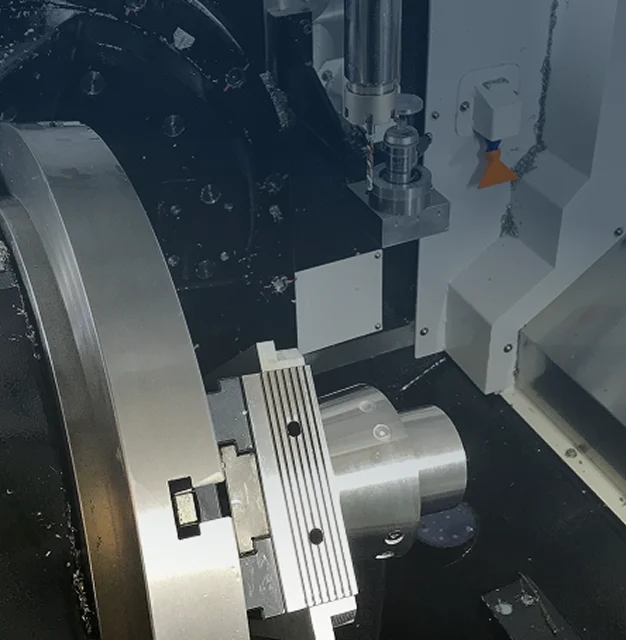

UTG High Precision Machining is a company specialized in precision mechanics: it manufactures parts through turning, milling, and grinding, and takes care of the CAD design of industrial equipment.

UTG was looking for a solution capable of managing the customer and item records in an orderly and precise manner, and to track the production phases of processing. The software in use proved to be inefficient in timing and not adaptable to the company’s internal workflows.

Objectives

/01

Monitor the work phases

The control tools that do not effectively follow the actual progress of the work do not allow for complete visibility of the processes, increasing the risk of errors, slowdowns, and delays in deliveries.

/02

Integrate collected data and industrial machines

Systems and software that do not communicate with each other make resource management inefficient and decrease the ability to adapt to new contracts or production requests.

/03

Enhancing the information

The factories generate large volumes of data that often remain unused due to a lack of appropriate tools to analyze and transform them into operational information, losing optimization and improvement opportunities.

Approach

After careful observation of the production lines and operational flows, we analyzed needs and limitations of the current management systems to truly understand the context.

The work focused on:

Ensuring the most accessible and seamless experience possible for operators in terms of user interface and usability in complex environments;

Integrate with existing machinery and systems, to promote a gradual and sustainable digital evolution that remains accessible in terms of costs and timelines.

Solution

Functionalities

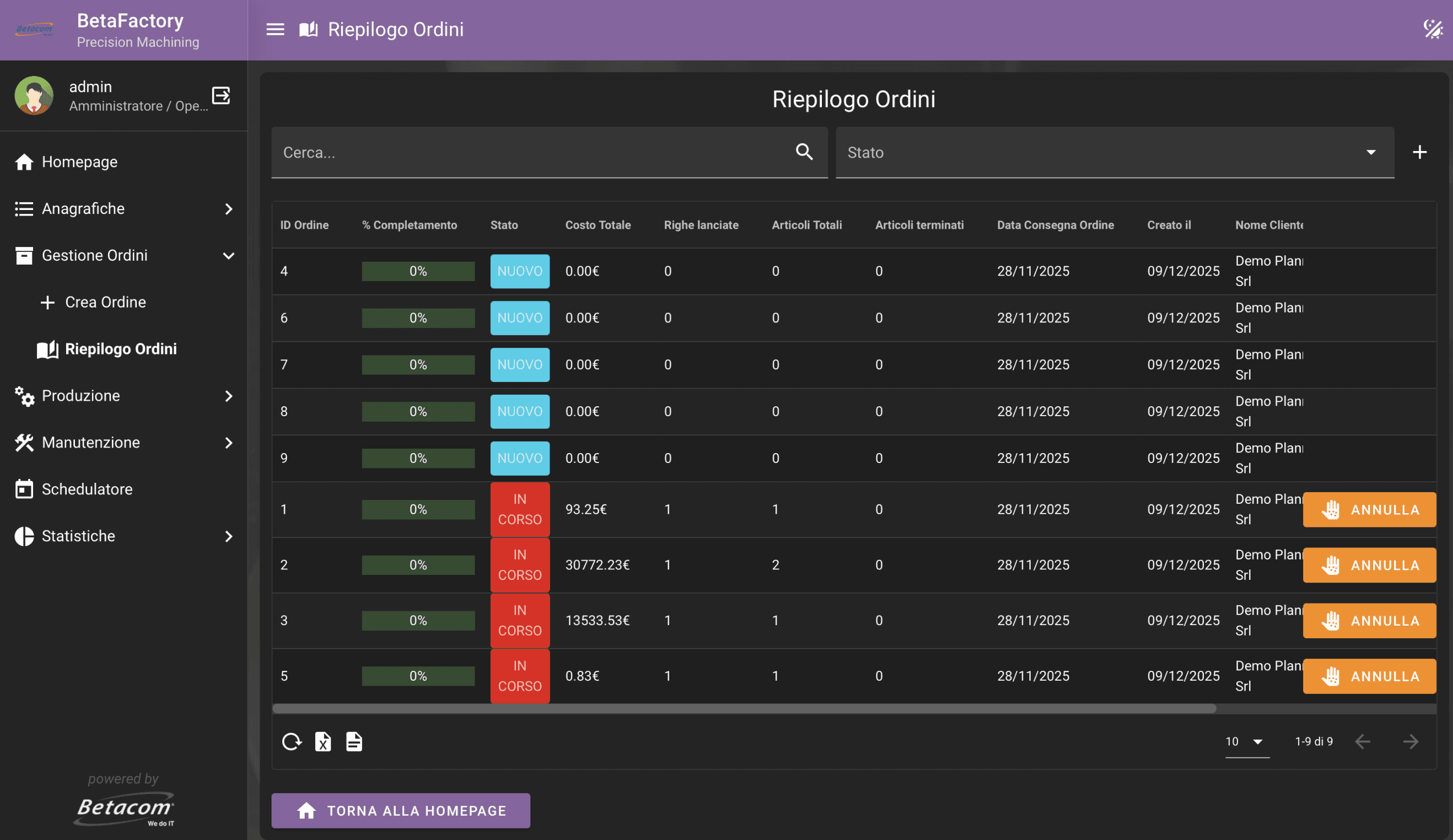

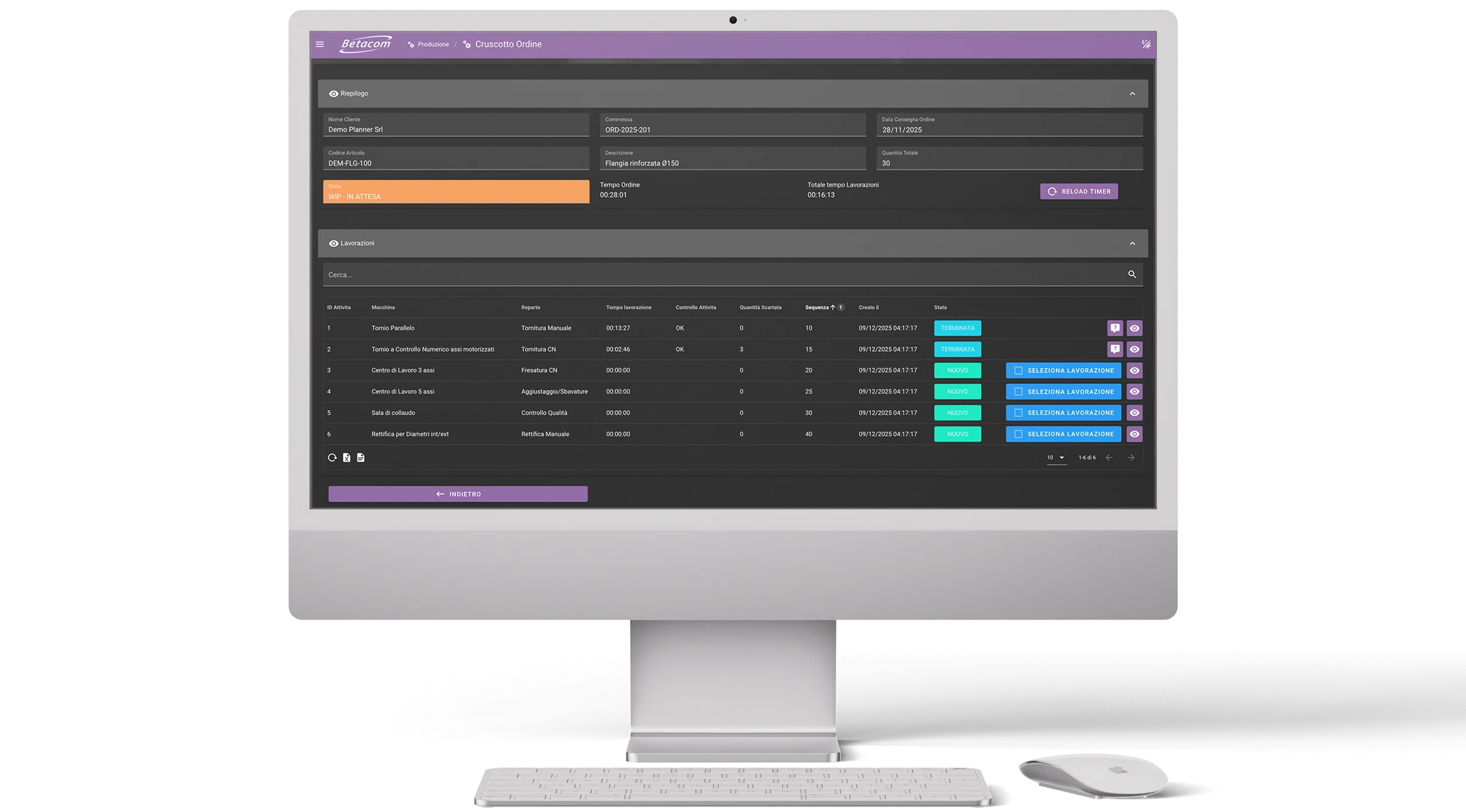

The management platform is highly customizable: it is capable of managing the administrative area of the records and the operational area for controlling the processing phases and production times.

The system allows monitoring, analyzing, and exporting production and performance data into specific reports useful for optimizing operations.

MONITORING

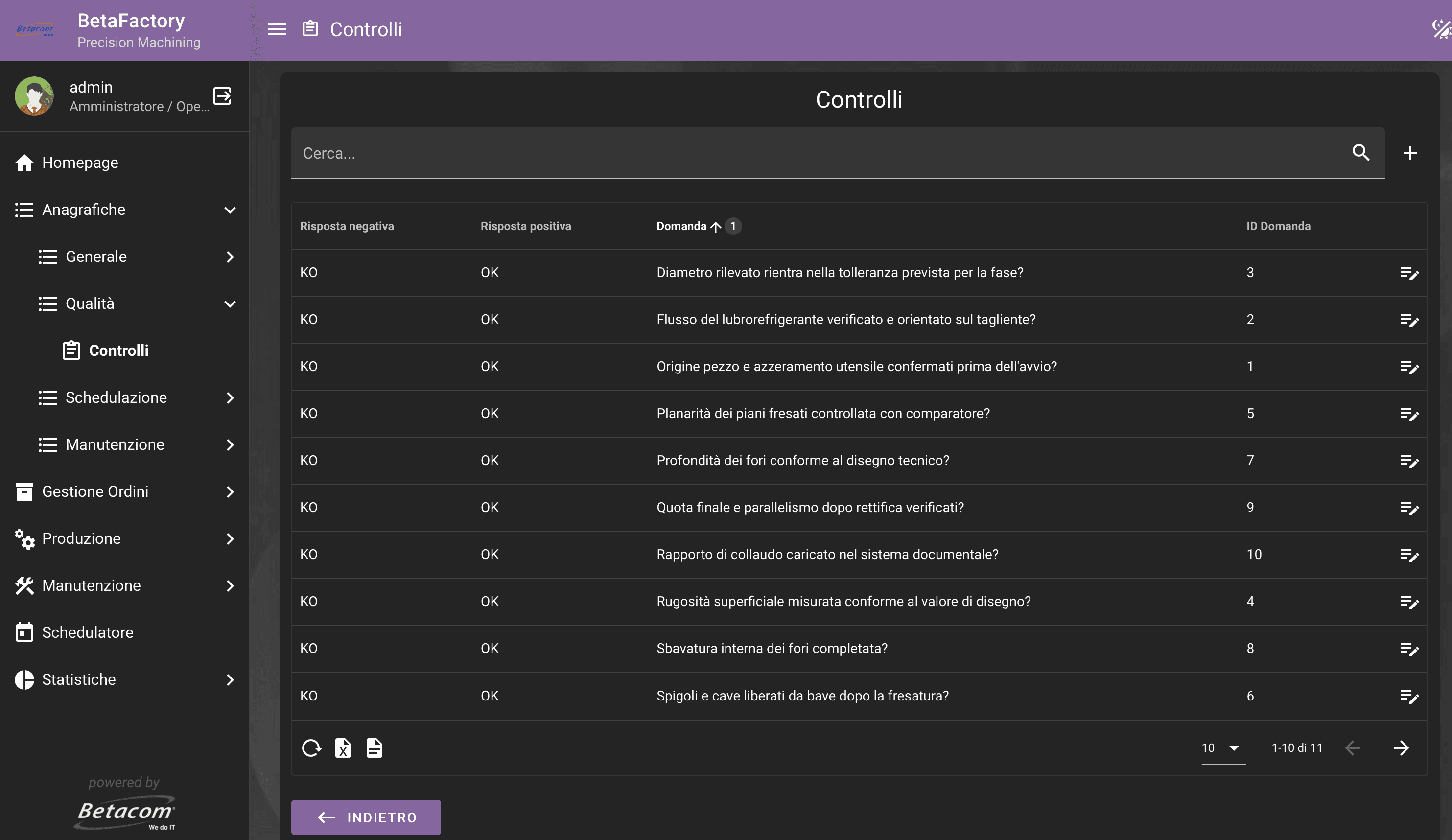

Through intuitive dashboards that are updated in real-time, it is possible to monitor quality control, performance analysis based on KPIs and detected anomalies.

Quality controls are recorded automatically. Out-of-range results are immediately flagged, ensuring a reactive and continuous control.

Quality control

ACTIVITY

Each operator is connected, tracked, and enabled only for the activities for which they are trained. Depending on the type of permissions, they can start, pause, complete operational phases, record activities and materials used, and report any anomalies.

Access to operational functions is through personal login or RFID key, ensuring security, traceability, and accountability.

Production orders

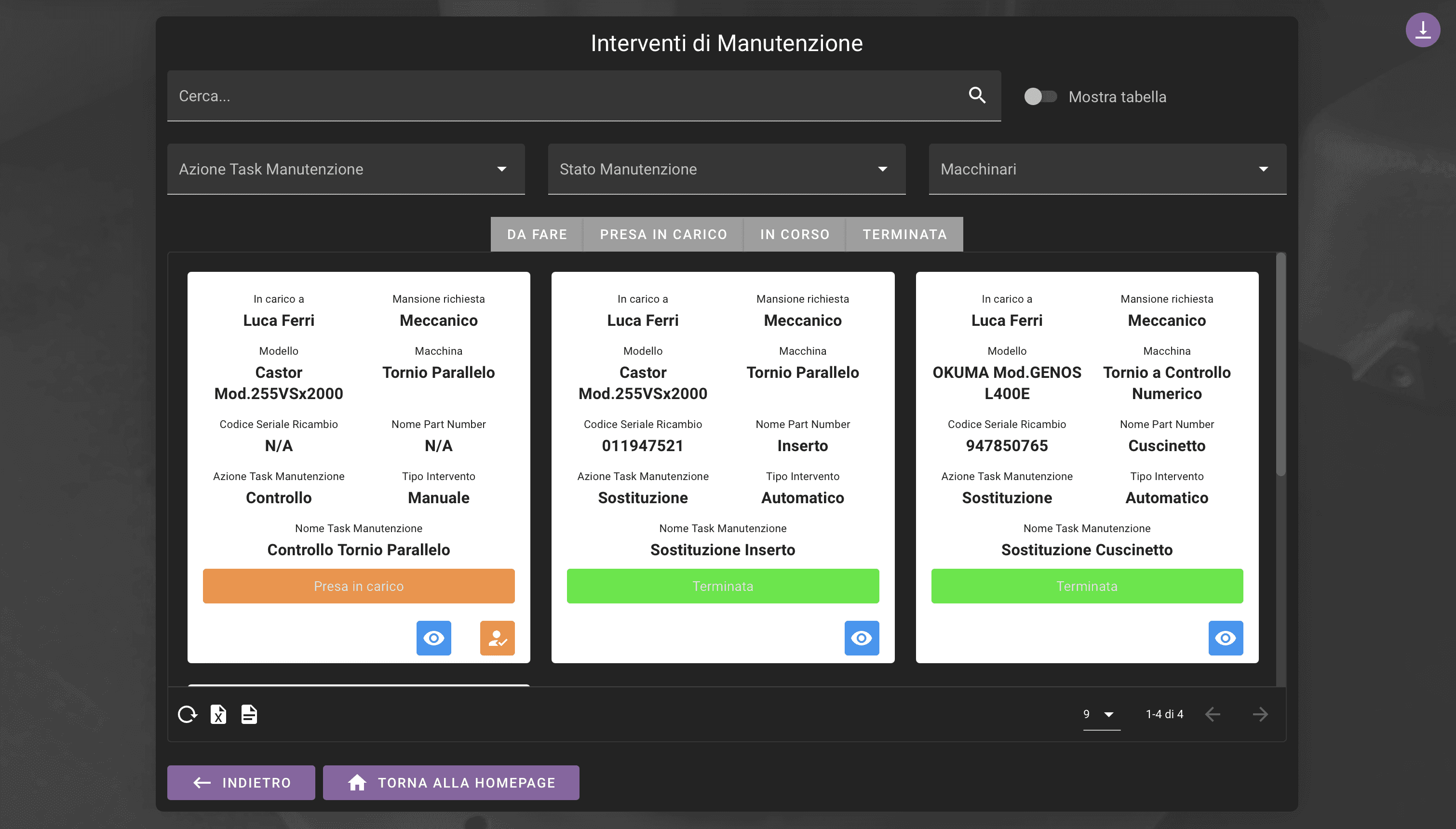

PREVENTION

We implement constant maintenance so that every phase of the production process is tracked to ensure transparency, compliance and control according to various industrial strategies (TBM, HBM, CBM).

Maintenance interventions are carried out only when needed or according to regulations, thus reducing machine downtime and keeping production flexible even in case of failures.

Planning MAINTENANCE

Results

Do you have a newly formed idea, a project to refine, or a specific need? Let's start from here.