Challenge

Cledan is an Italian company that mainly operates in the field of profiling through cold forming or bending of sheets. It is also specialized in industrial automation and mechanical processing.

Like many companies in the sector, Cledan needed to modernize the production data management system as the software it was using was obsolete, costly, and not very adaptable. Access to production information was insecure and fragmented; consequently, business processes were slowed down.

Objectives

/01

Analyze the critical issues to be more flexible

Identify the weaknesses of existing systems, map production flows, and understand the real needs of operators to define a solid basis for intervention.

/02

Ensure data security and usability

Centralize and protect production information, ensuring controlled, continuous, and transparent access without requiring communication between the various levels.

/03

Reduce maintenance costs and time

Simplify the management infrastructure by eliminating obsolete software and introducing modular and scalable tools to contain costs and management time.

Approach

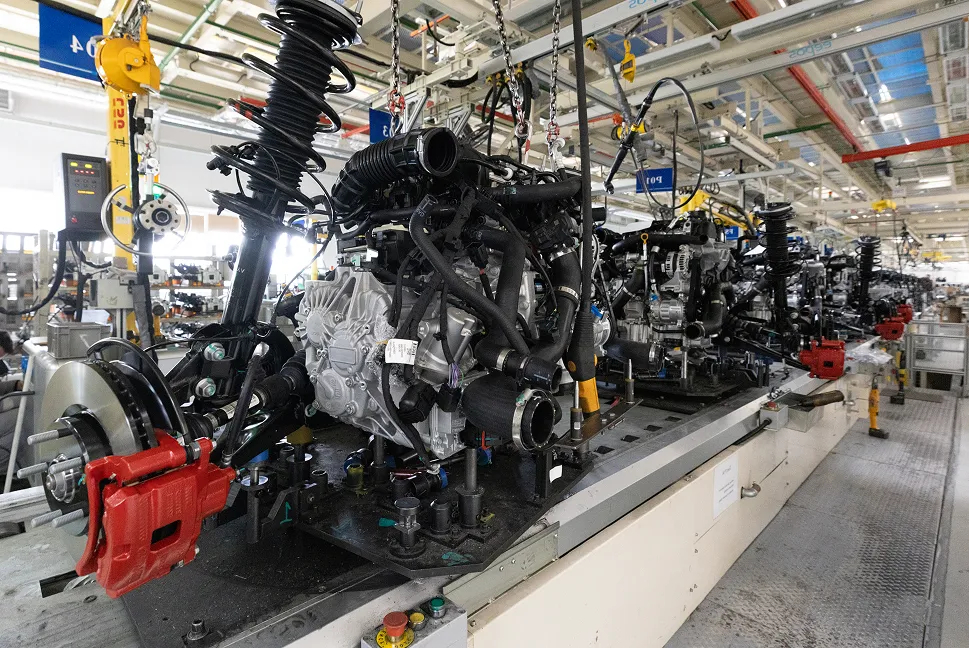

After careful observation of the production lines and operational flows, we analyzed needs and limitations of the current management systems to truly understand the context.

The work focused on:

Ensuring the most accessible and seamless experience possible for operators in terms of user interface and usability in complex environments;

Integrate with existing machinery and systems, to promote a gradual and sustainable digital evolution that remains accessible in terms of costs and timelines.

Solution

Functionalities

The system interacts with field devices to collect data directly from the plants. The information is processed and made available in a structured manner, providing technical personnel with a complete overview of the processes. Anomalies are detected in real-time, allowing timely interventions and a more efficient management of resources.

The system acquires heterogeneous data from the shop floor and transmits it to higher-level MRP, MES, or Cloud systems for analysis.

It supports various protocols and formats, including TCP, DATABASE, FILE XLSX JSON, PLC, MQTT, and HTTP, both in input and output.

Compatible with cloud (AWS, Microsoft Azure) and integrates with robots, production machines, PLCs, network drives, and sensors.

This is a SCADA/IOT application made up of various configurable modules that can be managed remotely, designed for real-time data collection, activity monitoring, and automation of inline operations.

At the core of the system is a traceability software developed according to the WCM methodology (World Class Manufacturing): it is a multi-platform, modular, scalable software that is based on interface abstraction and data normalization, which also serves as a dynamically gateway between the field and management systems.

Results

Do you have a newly formed idea, a project to refine, or a specific need? Let's start from here.