Ergonomics, efficiency, consistency

The project stems from the desire to digiitalize and simplify operational processes of a meat processing plant, maintaining the artisanal quality and ensuring accuracy in production management.

In a context where manual data management was slowing down operations and increasing the risk of errors, the goal was to create a platform that combined technology and ease of use, making the processes more readable, controllable, and supportive of the daily work of operators.

From the field to the code

The project stems from the desire to digiitalize and simplify operational processes of a meat processing plant, maintaining the artisanal quality and ensuring accuracy in production management.

In a context where manual data management was slowing down operations and increasing the risk of errors, the goal was to create a platform that combined technology and ease of use, making the processes more readable, controllable, and supportive of the daily work of operators.

Behind the interface

The system is based on a traceability platform that collects real-time data along the entire production chain.

The information is automatically acquired and returned to the operator in a clear and immediate manner, transforming the complexity of the process into simple and guided actions.

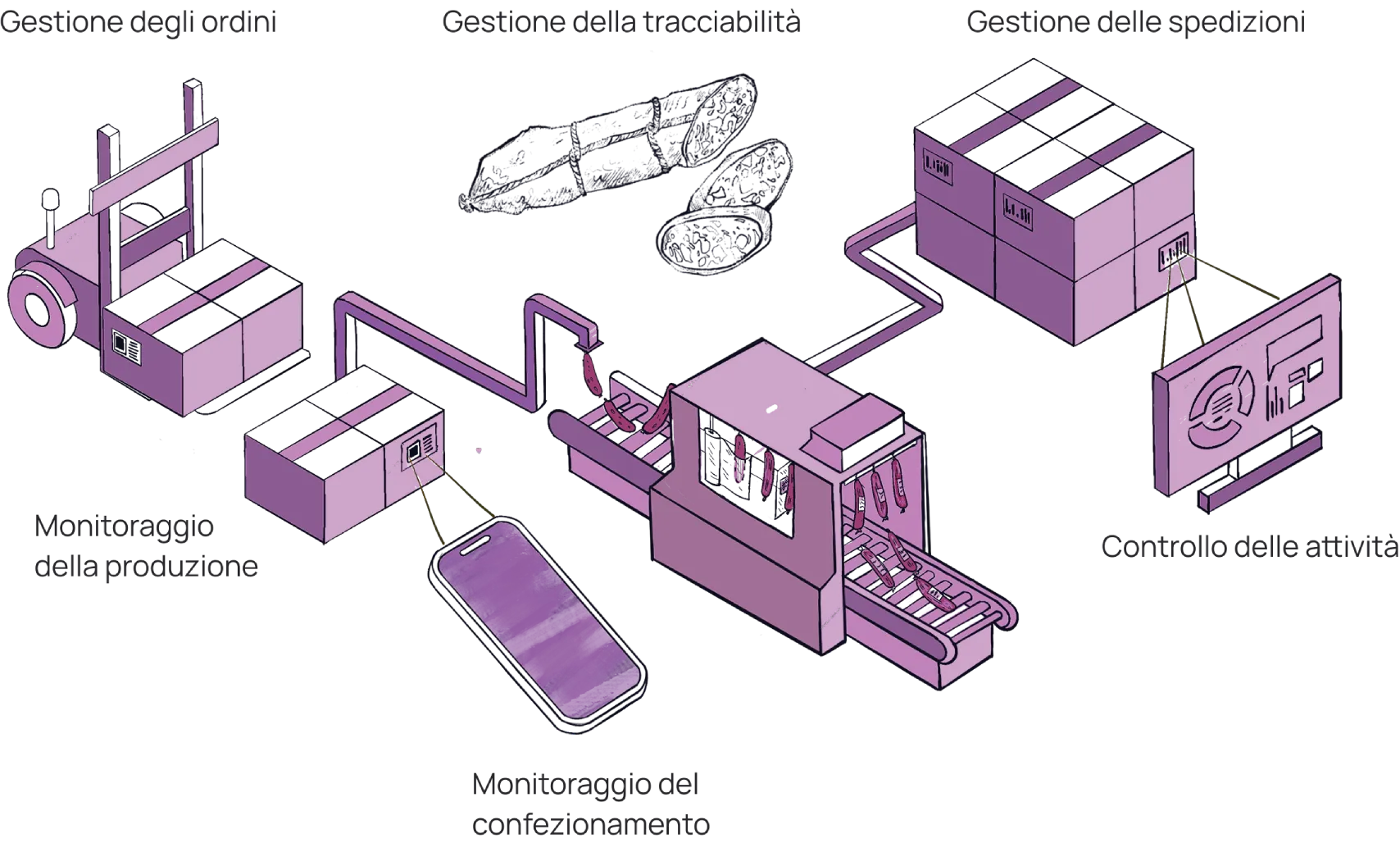

How it works

The platform automatically acquires data through sensor technology, machine vision, and RFID, allowing for real-time information collection without the need for manual intervention.

It is accessible from computers, tablets, and barcode readers, offering maximum flexibility. Moreover, it easily integrates with the management system and the courier portal via API, optimizing shipment management.

The information is collected and organized in a structured manner, so it is always available throughout the process.

From the creation and planning of orders to the traceability of raw materials and products, the system supports every phase of production.

The monitoring of production activities and packaging allows for checking compliance, identifying any anomalies, and managing shipments and reporting in a coordinated manner, providing a continuous and reliable view of the process.

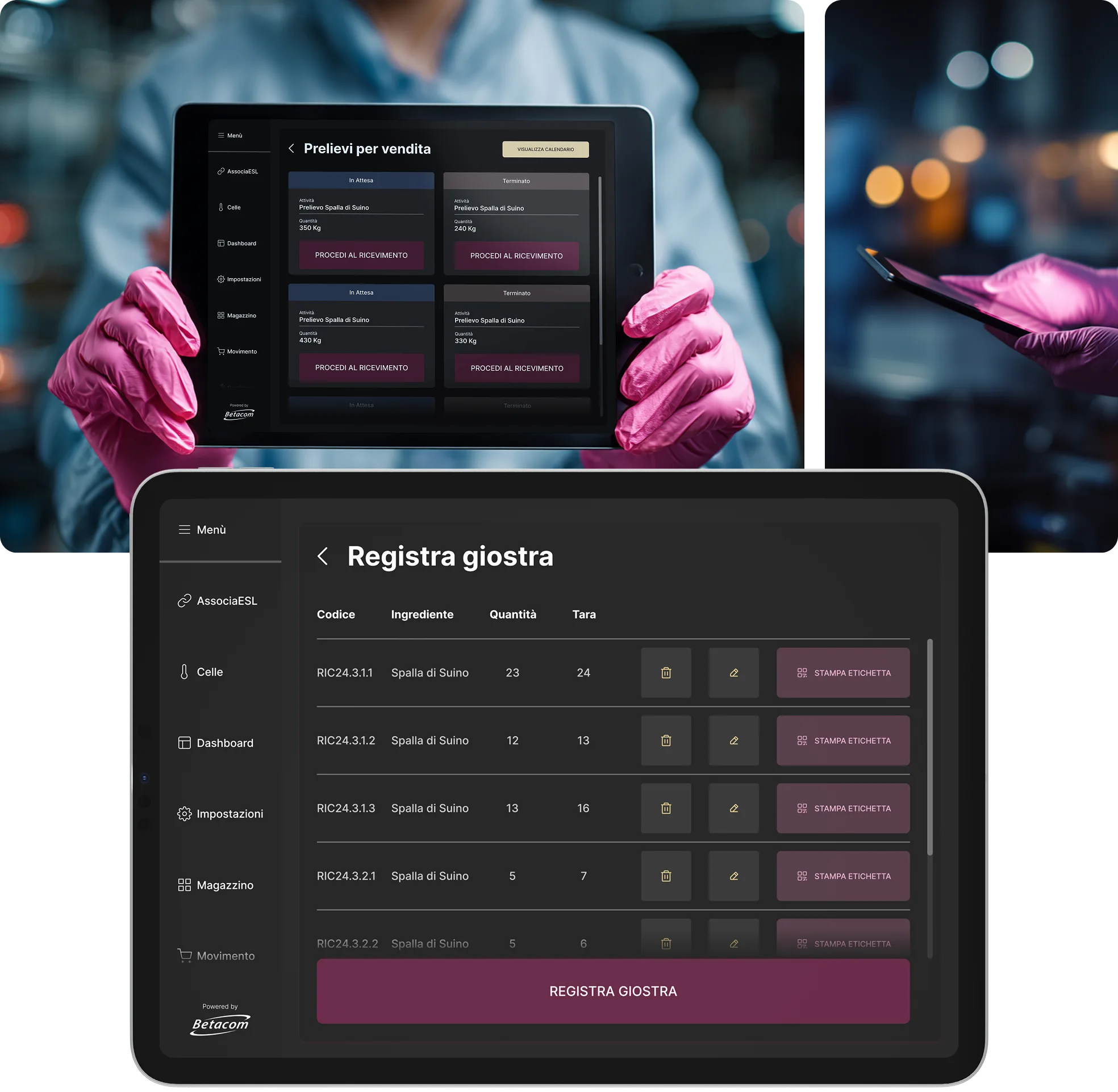

Clarity in flows

The system guides the operator in every phase of the process: from receiving goods to processing, up to aging.

The actions are direct, the steps simplified, and the visual feedback clear.

Each section has been designed to offer a smooth and understandable experience at a glance, reducing margins of error.

Human factors

We have integrated the principles of cognitive and physical ergonomics:

reduction of mental load and better attention management;

interfaces optimized for use with gloves;

calibrated palettes and contrasts for low-light industrial environments.

A design built around the operator, not the machine.

Hierarchy and states

Primary button

Color text

#FFFFFF

Background

#59213C

Border

///

Default

main actions

Accent button

Color text

#1A180E

Background

#DCC48E

Border

///

Default

confirmations and significant operations

navigation and support

Secondary button

Color text

#D3ADBF

Background

#34272D

Border

///

Default

Tertiary button

Color text

#DCC48E

Background

#2C2C2C

Border

///

Default

Visual coherence and brand identity

The interface reflects the identity of Gabba Salumi, blending tradition and innovation. The color palette conveys solidity, warmth, and artisanal quality. Every visual element contributes to creating a coherent, recognizable, and accessible digital environment.

A UI designed for the context

The interface operates in dark mode, ensuring visual comfort and reducing glare in productive areas.

The cards and modals maintain high contrast, while the 40×40px icons and large buttons simplify interaction even when wearing work gloves.

The result is a scalable, consistent design system that can be easily extended to future evolutions of the system.

The result

The new management system offers a complete and real-time view of the production processes, simplifying the management of activities and improving collaboration among operators.

Every interaction is more immediate, every piece of information more accessible, every process more secure.

A project that values the competence of people through a design conceived for those who work every day in the field.

Do you have a newly formed idea, a project to refine, or a specific need? Let's start from here.